Overview:

The DJI Mavic 3 Enterprise is a drone designed for commercial applications such as mapping, surveying, inspection, and search and rescue. It features advanced technology such as obstacle avoidance, a 4K camera with a 20-megapixel sensor, and a 46-minute flight time. This technology review focuses on the Mavic 3 Enterprise's technical functionality for commercial roofing. We explore its possible applications, advantages, and disadvantages and compare it to other technologies in the industry. Our findings suggest that the Mavic 3 Enterprise is a powerful tool for commercial roofing applications, with its high-resolution camera, long battery life, and obstacle avoidance features.

Introduction:

The DJI Mavic 3 Enterprise is a drone designed for commercial applications that require high-resolution imaging, obstacle avoidance, and long battery life. It has advanced features make it an ideal tool for various industries, including surveying, inspection, and search and rescue. As a commercial roofing expert with over a decade of experience, I can attest to the importance of regular roof inspections for maintaining the structural integrity of a building. The Mavic 3 Enterprise is a powerful tool that can help roofing professionals perform inspections safely, efficiently, and cost-effectively.

The drone features a 4K camera with a 20-megapixel sensor, allowing for high-quality roof surface imaging. It can capture detailed images and videos, making identifying any issues or damage easier. The drone also has obstacle avoidance technology, which enhances its safety and makes it easier to operate around buildings and other structures. The drone's features make it an excellent tool for commercial roofing inspections. The Mavic 3 Enterprise has a long battery life of up to 46 minutes, which allows for longer flights and more extensive coverage. Extensive coverage.

Possible Applications:

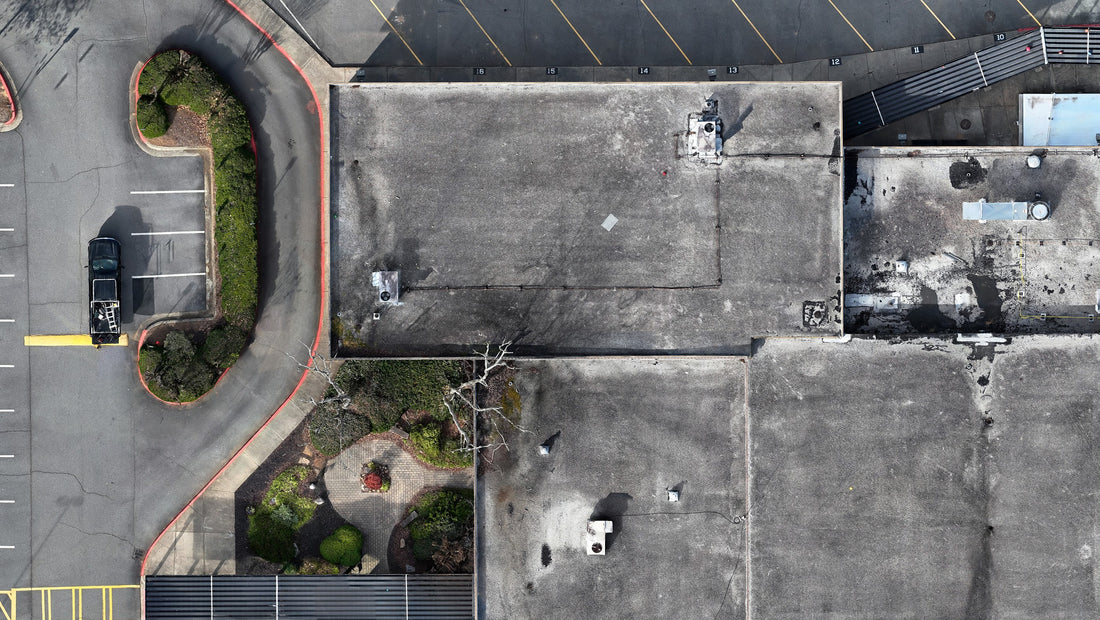

The DJI Mavic 3 Enterprise drone has several possible applications in commercial roofing. Its advanced technology makes it a valuable tool for roofing professionals who want to inspect and assess the substrate. The drone can capture high-resolution images and videos, providing a detailed analysis of any issues or damage to the roof. Roofing professionals can use drones to manually examine areas that are difficult or unsafe to access.

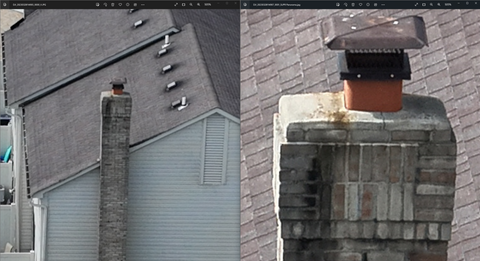

The Mavic 3 Enterprise's high-quality camera can capture images of the roof's surface with great detail, allowing roofing professionals to quickly identify issues such as ponding water, debris, or damaged areas. The drone's obstacle avoidance technology helps keep it safe and prevents it from crashing into buildings or other structures. This feature is handy when inspecting the roof's edges, which can be dangerous to access manually.

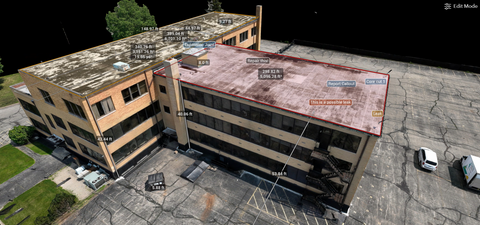

The drone's ability to create 3D models of the roof's surface makes it a valuable tool for roofing professionals. These models can create accurate roof plans and CAD drawings to efficiently plan and execute repairs or replacements. The Mavic 3 Enterprise's long battery life allows for more extensive coverage. It enables roofing professionals to complete inspections more quickly.

As someone with commercial roofing experience, the Mavic 3 Enterprise drone offers a safer and more efficient alternative to traditional manual inspections or other inspection techniques such as cherry pickers or rope access. Using the Mavic 3 Enterprise, roofing professionals can access areas that are challenging to reach manually, such as steep roofs or tall buildings. The drone's high-resolution camera and 3D modeling capabilities make identifying and diagnosing issues easier, leading to more effective repairs and maintenance.

Advantages:

- High-resolution Camera: The Mavic 3 Enterprise has a 4/3 CMOS 20-megapixel sensor that can capture detailed images and videos of the roof surface. This high resolution allows for accurate analysis and diagnosis of any issues or damage, such as cracks, leaks, or wear and tear. Additionally, the camera has a 3-axis gimbal stabilization system, which helps to reduce camera shake and produce smoother, more stable footage.

- Obstacle Avoidance: The drone has a 6-directional obstacle sensing system that uses advanced sensors and algorithms to detect and avoid obstacles. This feature is handy for commercial roofing inspections, where the drone may need to navigate buildings, power lines, and other structures. The obstacle avoidance system enhances safety and reduces the risk of crashes or collisions.

- Long Battery Life: The Mavic 3 Enterprise has a flight time of up to 46 minutes, significantly longer than many other drones on the market. This extended battery life allows for longer flights and more extensive coverage, which can be especially beneficial for large or complex roofing structures. The drone also has a maximum flight range of 15 kilometers, which enables it to cover a wide area and capture detailed images and videos from different angles and perspectives.

- 3D Mapping and Modeling: The Mavic 3 Enterprise can capture 3D models of the roof surface, allowing for accurate estimates and assessments. This feature is handy for construction projects, where professionals must understand the roof structure and its components. The 3D models can be used to identify any potential issues or design flaws and can also help to improve communication and collaboration among team members.

- Safe and Efficient: The Mavic 3 Enterprise provides a safe and efficient solution for commercial roofing inspections. Unlike manual checks, which can be time-consuming and dangerous, the drone can quickly and easily capture detailed images and videos of the roof surface from a safe distance. Additionally, the drone's advanced features, such as obstacle avoidance and long battery life, enhance its efficiency and effectiveness, reducing the time and resources required for inspections and assessments.

Disadvantages:

- Payload: One significant disadvantage of the Mavic 3 Enterprise for commercial roofing applications is its limited payload capacity. While the drone's high-resolution camera is advantageous, it lacks abilities such as thermal imaging or environmental sensors. This limitation can be a disadvantage for businesses that require multiple types of equipment for their inspections and surveys, as they may need to use various drones or switch out equipment during flights. *** Adding a Mavic 3 Thermal will cover most roofers' needs and maintain a similar platform for batteries, chargers, cases, and controllers.

- Complexity: The Mavic 3 Enterprise is a complex technology that requires careful handling and maintenance to prevent accidents or damage to the drone or the building. Professionals who wish to use the drone for commercial applications must complete training and certification programs to ensure they have the necessary skills and knowledge to operate the drone safely and efficiently. This requirement can add additional costs to businesses that wish to adopt the technology.

- Weather: weather conditions can affect the drone's flight performance. Rain, snow, high winds, or other adverse weather conditions can make it unsafe to fly the drone or affect the quality of the images or videos captured. This limitation can cause delays in inspections and surveys and increase the risk of accidents or damage to the drone or the building.

- Cost: the cost of the Mavic 3 Enterprise may be a disadvantage for some businesses. The drone is a high-end technology with a premium price tag, which may be prohibitive for smaller companies or those with limited budgets. The cost of purchasing the drone and training, maintenance, and repairs can add up quickly, making it difficult for some businesses to justify the investment.

Comparisons:

Manual inspections have long been the traditional method for inspecting roofs. Roofing professionals climb onto the roof and visually inspect it for any issues or damage. While we use this today, it can be time-consuming, dangerous, and sometimes ineffective. Manual inspections require extensive training and planning for accurate data capture, exposing them to hazards such as falls and electrical wires. Furthermore, manual inspections may not accurately represent the condition of the roof surface due to limitations in visibility and access or lack of data collection by the inspector.

Cherry pickers and boom lifts. These machines can lift people and equipment to high heights, allowing for a closer inspection of the roof surface. However, they can be costly to rent or purchase, and the location and terrain of the building often limit their access. Additionally, they may cause damage to the property, and their reach may not be suitable for all roof types.

Rope access techniques are another option for roof inspections. This method involves professionals abseiling from the top of the building to inspect the roof surface. While this method provides access to areas that are difficult to reach, it can be dangerous and requires specialized training and certification. Furthermore, it may only be suitable for some roof types or locations.

When compared to these other technologies, the DJI Mavic 3 Enterprise drone offers several advantages:

- It provides a safe inspection solution, eliminating professionals needing to climb onto all roof surfaces.

- It provides overview images and 3d models of the roof surface, making identifying any issues or damaged locations easier.

- It is more cost-effective than other methods, such as renting cherry pickers or purchasing rope access equipment.

- Drones reduce the risk of misinformation or return trips to job sites.

Conclusions/Further Plans:

The DJI Mavic 3 Enterprise is a cutting-edge technology that immensely benefits the commercial roofing industry. Its high-resolution camera, obstacle avoidance technology, and long battery life make it an ideal tool for conducting detailed and accurate inspections, assessments, and modeling of roofs. Additionally, the Mavic 3 Enterprise's ability to provide 3D models and maps allow professionals to identify problems more efficiently, leading to faster repairs and lower business costs.

However, the Mavic 3 Enterprise is not the only drone technology available. Other popular drone models include the Phantom 4 RTK and the Matrice 300 RTK. The Phantom 4 RTK is known for its accurate GPS and mapping capabilities that the Mavic 3 shares with the addition of the RTK module. It is a good tool for aerial surveying and construction site monitoring, but the Mavic 3 outperforms it. On the other hand, the Matrice 300 RTK is a more advanced drone with higher payload capacity and more robust obstacle avoidance technology. The starting price without a camera over double that of the Mavic 3 makes it less affordable. While these drones offer unique advantages, the Mavic 3 Enterprise's affordability and flexibility make it an attractive choice for businesses in the roofing industry.

To further maximize the potential of the Mavic 3 Enterprise, businesses can consider integrating it into their regular maintenance and inspection processes. For example, the drone can detect ponding, debris, and deterioration in the roof surface, allowing for early intervention and repairs. Additionally, businesses can leverage the technology to provide more value to their clients by offering drone inspection services. The Mavic 3 Enterprise's high-resolution camera and 3D mapping capabilities can provide clients with detailed reports of the condition of their roof surfaces, helping them make informed decisions about repairs and maintenance.

Furthermore, businesses can explore the potential of using artificial intelligence (AI) and machine learning (ML) algorithms to analyze the data collected by the Mavic 3 Enterprise. By leveraging these technologies, businesses can automate analyzing roof surfaces and identifying issues, leading to faster and more accurate repairs. For instance, you can use AI and ML algorithms to identify patterns in the data collected by the drone, such as areas with a high risk of leaks or damage, enabling businesses to prioritize repairs and maintenance activities.

In conclusion, the DJI Mavic 3 Enterprise is a powerful tool that immensely benefits commercial roofing. Its affordability, flexibility, and advanced features make it an attractive choice for businesses in the industry. By integrating the technology into their regular maintenance and inspection processes, companies can identify issues early, leading to faster repairs and lower costs. Moreover, by leveraging the potential of AI and ML, businesses can automate the process of analyzing roof surfaces and identifying issues, leading to more efficient and effective maintenance practices.

Follow Kerrick Willis and GeoSpatial Integrations (GSI) for more drone, roofing, and photogrammetry content.