A Connection of Vision

In a realm where innovation intersects with tradition, GeoSpatial Integrations LLC (GSI) and Centerpoint Connect have formed a strategic partnership, setting a new benchmark in the roofing industry. This collaboration is rooted in a shared vision of placing people first, underpinned by a relentless focus on delivering functionality that enriches the end-user experience. Our journey into this alliance was not of sheer market opportunity but a profound understanding and personal experience in roofing.

GSI and Centerpoint Connect embody people-centric businesses striving to make a tangible difference in roofing contractors' operations, communicate, and deliver value to their clients. Our grounding in the roofing industry isn't merely theoretical; it's built upon years of hands-on experience, which has ingrained in us a deep-seated understanding of the challenges and potentials within this sector.

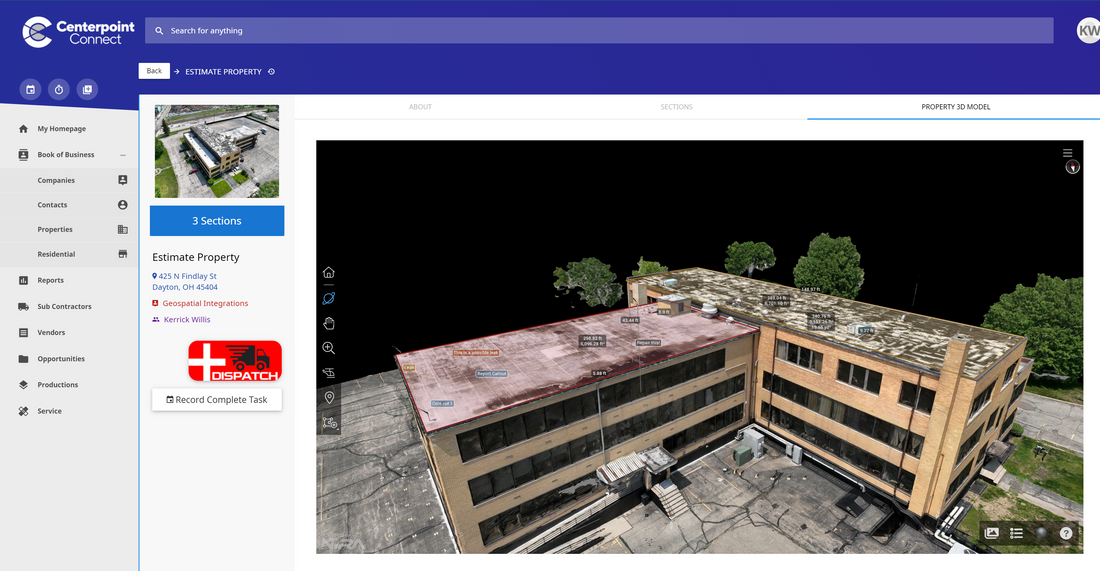

The cornerstone of our partnership is to amalgamate the prowess of drone technology with the robust, user-friendly platform of Centerpoint Connect, thereby unlocking a new dimension of functionality and efficiency. The fusion of these technologies is not a mere upgrade; it's a paradigm shift that propels roofing contractors into a new era of operational excellence and client satisfaction.

Traditionally, the roofing industry has relied on manual inspections, 2D imagery, and conventional photos and videos to assess, quote, and execute projects. While these methods have merits, they are often time-consuming, labor-intensive, and need more precision and clarity than modern projects demand.

Enter the new realm of 3D modeling, brought to life by the synergy between GSI's drone technology and Centerpoint Connect's innovative platform. This novel approach transcends the limitations of 2D imagery and standard media, offering a comprehensive, accurate, and interactive view of roofing projects. With the ability to measure, inspect, and annotate 3D models from anywhere without the constraints of file size, we are rewriting the narrative of what's possible in roofing project management.

Bridging the Technological Divide: Traditional vs. New Approaches in Roofing Inspections.

The roofing industry, steeped in tradition, has long relied on manual methodologies for inspections and assessments. The conventional tools of the trade—ladders, tape measures, and the seasoned eye of an experienced contractor—have been the bedrock of roofing inspections. However, as the adage goes, "The only constant in life is change." The advent of technology, particularly drone technology, and 3D modeling, heralds a new era of roofing inspections that enhance accuracy and significantly trim down the time and resources required.

Traditional Approach:

-

Manual Inspections: Traditional roofing inspections involve a team of skilled inspectors navigating the roof's surface. This method, although

hands-on, is labor-intensive, time-consuming, and carries inherent safety risks. The data collected is often subject to human error, potentially leading to inaccurate estimates and project scopes.

- 2D Imagery and Standard Media: The reliance on photos, videos, and 2D drawings as the primary means of documenting roofing conditions has drawbacks. These media often need more depth, clarity, and precision for accurate analysis. This inadequacy becomes a significant contention between the estimating and production departments. Estimators working with this limited information may create project scopes that overlook critical issues or misinterpret conditions. On the other hand, superintendents on the production side may find themselves grappling with unforeseen challenges once on-site, leading to project delays, cost overruns, and a palpable strain between the two departments. The lack of a standard, accurate visual language leads to a blame game, making collaboration difficult and fostering a culture of discord rather than unity.

New Approach with 3D Modeling and Drone Technology:

- Drone-Captured Data: Their high-resolution imaging capabilities allow for rapid data capture. Training roofers to operate drones eliminates the need for a separate individual to capture data, speeding up the data collection process and reducing the carbon footprint by requiring fewer people on-site, making the approach greener, more efficient, and more effective.

Bringing together two worlds

Integrated Platforms: Integration with platforms like Centerpoint Connect provides a unified environment for interacting with, analyzing, and sharing 3D models. Measuring, inspecting, and annotating these models from anywhere enhances communication between estimating and production departments. With a more transparent, accurate depiction of the project, estimators can create more accurate scopes, and superintendents can better prepare for on-site challenges. Shared visual language fosters a better understanding of collaboration and significantly reduces conflicts arising from misinformation or lack of information.

Breaking Down the Media:

3D Models:

- 3D models enable precise horizontal and vertical measurements, adding a layer of insight and confidence to each estimate.

- Accessible from any device with an internet connection, 3D models allow stakeholders to view projects of any size from anywhere. This capability revolutionizes collaboration, marketing, and sales by bringing the roof to stakeholders without leaving their offices.

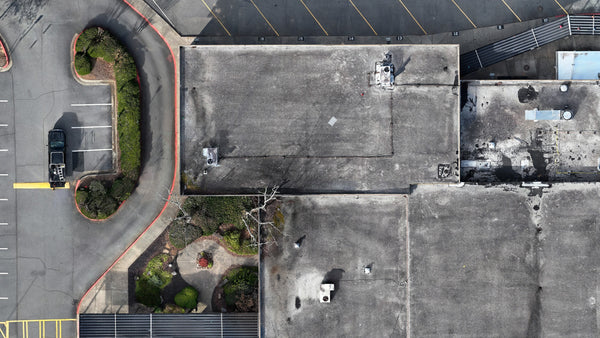

2D Orthomosaics:

- Replacing conventional tools like Google imagery, 2D orthophotos boast an average of 10x greater resolution and 4x the resolution of a standard eagle view manned flight report.

- The crystal clarity of 2D orthos empowers users to count, measure, and locate all air-visible penetrations, acting as a super tool for roofing projects.

- Incorporating these images into estimates with a simple scale constraint enhances measurement accuracy.

- Utilize 2D orthos as a map for your roof plan, showcasing a more accurate project unfolding.

Photos:

- Capturing the roof and building is simplified with a few tips, enabling the acquisition of branded images throughout the project lifecycle for sales, marketing, or project management. The clarity and color richness of these images are bound to impress.

Video:

- Videos serve as a quick, alternative method to get a project overview, particularly useful for individuals less accustomed to 3D models or those preferring a different visual perspective. A 1 to 2-minute orbit around the roof can provide a swift yet thorough overview.

- Before and after shots compiled into videos create compelling marketing content, aiding in scaling your business year after year.

Transitioning to the New Approach: In-House vs. Outsourced Pilots

Incorporating drone technology in roofing inspections is not merely about adopting new gadgets; it's about embracing a paradigm shift that enhances operational efficiency, accuracy, and safety. As companies transition to this new approach, a pivotal decision lies between employing in-house drone pilots or outsourcing this expertise. Each path carries its set of advantages and considerations.

In-House Drone Pilots:

- Alignment with Company Values: In-house pilots are immersed in the company culture and align with its values, quality standards, and operational processes. This alignment fosters a higher level of accountability and quality control.

- Quick Response and Communication: Having pilots as part of your team facilitates rapid response times to project needs and enhances communication within the project ecosystem.

- Cost Efficiency Over Time: While the initial investment in training and equipment might be substantial, having in-house pilots can be cost-effective in the long run, especially for companies with a high volume of projects.

- Skill Development: Investing in training for in-house pilots builds a skilled workforce and instills a sense of value and growth, which can be motivating and retention-enhancing.

Outsourced Drone Pilots:

- Lower Initial Investment: Outsourcing pilots may require a lower initial investment as they come with their equipment and expertise.

- Flexibility: It's a flexible solution for companies with infrequent drone needs or those in the early stages of integrating drone technology.

- Access to Specialized Expertise: Outsourced pilots often have a wide range of experience and may provide specialized expertise in drone operations.

- Reduced Management Overhead: Outsourcing reduces the management and administrative overhead of maintaining an in-house drone team.

Making the Decision:

The decision between in-house and outsourced pilots hinges on various factors, including the volume of drone-needed projects, budget considerations, the importance of closely aligned operations, and the company's long-term vision concerning drone technology.

GeoSpatial Integrations LLC's experience showcases the tangible benefits of nurturing in-house drone expertise with a 240% increase in projects captured by scaling up with an additional in-house pilot, new drones, and refined workflows — 17 projects and 21 buildings within a month. This case exemplifies the scalability and efficiency gains attainable with a well-structured in-house drone program.